News

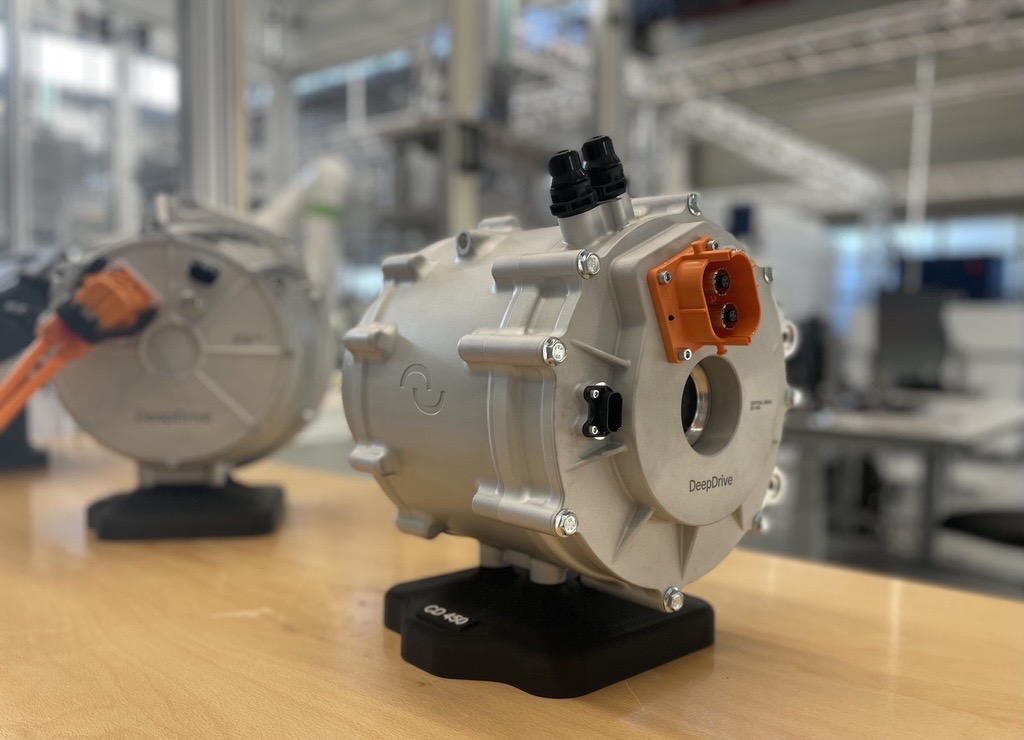

Introducing DeepDrive’s CD 450

CENTRAL DRIVE

2025 / 04 / 09

At this year’s IAA Mobility in Munich, DeepDrive is showcasing its full portfolio of next-generation electric drives. One of the highlights is our CD 450: a compact and lightweight central drive unit built on our patented Dual Rotor, Radial-Flux technology. With peak efficiency more than 97% for the motor including inverter, up to 300 kW of peak power, and a planetary gearbox with a co-axial output shaft, the CD 450 sets new benchmarks for performance and cost efficiency in compact and mid-sized vehicles, as well as premium all-wheel-drive applications

WHY A CENTRAL DRIVE?

“In-Wheel motors are incredibly exciting, but they’re still unfamiliar territory for many OEMs,” explains Zoé Weicherding, Engineering Specialist and one of the two Product Owners for the Central Drive at DeepDrive. “The Central Drive gives our Dual Rotor technology a more conventional framework – one that manufacturers can integrate more easily into existing vehicle concepts.”

The Central Drive is designed to bridge innovation with practicality. While In-Wheel drives push efficiency to new levels, the CD 450 focuses on cost, packaging and ease of adoption. Its power density enables an extremely compact design, which is crucial given the tight installation spaces in modern EV architectures.

A COMPACT, HIGHLY INTEGRATED DESIGN

One of the key engineering challenges was integrating the Dual Rotor machine with a SiC inverter in a single, compact EDU. “Space was extremely limited, especially for the inverter electronics,” says Zoé. “It required close collaboration across electrical, mechanical and thermal design to ensure every component could be efficiently cooled and packaged.”

The result is a highly integrated system where the inverter sits directly behind the motor, minimising footprint while maximising efficiency.

WHY A PLANETARY GEARBOX?

To achieve high torque conversion in a compact footprint, the CD 450 uses a planetary gearbox with a co-axial output shaft. “This layout fits perfectly with our machine geometry,” Zoé explains. “It allows us to keep the package cylindrical and simple to integrate, while also improving efficiency and reducing cost.”

Because the gearbox requires only one bearing, additional bearing losses are eliminated and assembly complexity is reduced. Fewer parts mean fewer steps in production – and ultimately a lighter, more cost-effective EDU.

COOLING AT 300 KW

Handling up to 300 kW peak power in such a compact design requires advanced cooling strategies. The CD 450 uses a single cooling channel with two functions: Colling the inverter and the motor. Inside the machine, cooling fins and an active air circulation system ensure that the rotor stays within safe operating temperatures.

Unlike In-Wheel motors, where airflow is generated externally, the Central Drive rotor acts like a small radial compressor, constantly moving air across the cooling fins and through the air gaps. Combined with our stator design that enables efficient single-sided cooling, this ensures robust thermal stability even under high continuous load.

FUTURE STANDARD – READY TODAY

With the Central Drive, DeepDrive combines the familiar layout of a central EDU with a breakthrough motor topology. For OEMs, this means a solution that integrates seamlessly into existing architectures – while offering clear advantages in cost, packaging, and performance.

The CD 450 will be presented in updated design at IAA Mobility 2025, Hall A1, Booth C23, alongside our In-Wheel Drive and newly developed MG 250 Generator.